Vacuum Clamping

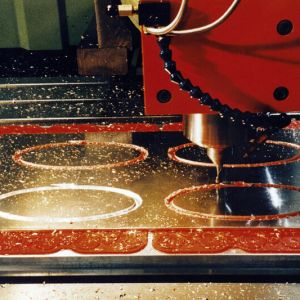

VAC-MAT vacuum clamping system

Application

Wide spectrum of different workpiece forms can be clamped for

- Grinding

- Milling

- Drilling

- Five side treatment including milling into the Vac-Mat

Advantages

- Strong hold down force

- Clamping surface with a high friction value

- Milling through of outer and inner contours

- Accurate and precise cut outs due to the fact that workpiece can be milled through into

- VACMAT leaving a clean cut out

Handling

- Set up reduced to seconds as fitting of single rubber seals become obsolete. Surface friendly material which avoids scratching of workpiece surface area. No extra clamping fixture needed.

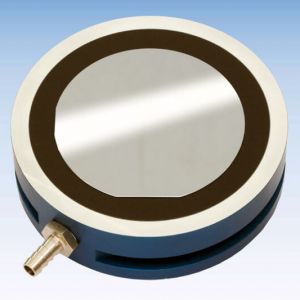

Sinter metal and Metapor chucks

These chucks have a porous surface area made out of sinter bronze, ceramic or porous aluminium depending on application and workpiece. METAPOR opens a whole new perspective for different clamping solutions.

Application

Preferred workpieces:

- Thin walled (i.e. paper, foils, plate bars, metal strips)

- Fine (i.e. optical)

- Soft materials (i.e. rubber)

For work such as

- High precision measuring

- Precision milling

- Silicon wafer production

Advantages

- Due to the absence of grooves and holes workpieces are not deformed for instance on inserts in the clamping area

- Milling through workpiece is possible with using our Friction booster

- METAPOR has different quality grades and can also qualify for clean room surrounding (Kl.10)

Handling

- Modular chucks can be interconnected to enlarge the surface area

- Custom build possible

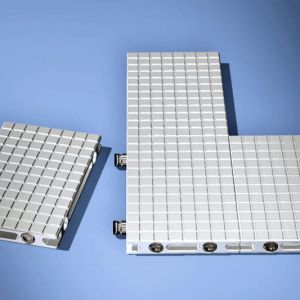

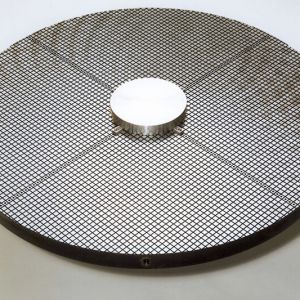

Grid type vacuum chucks

Applications

For simple shaped workpieces with a rough surface and heavy duty milling

- Grinding

- Milling

- Turning

Advantages

- Strong hold down surface

- Universally applicable

- Secure clamping of rough workpieces due to high friction properties

- The o-shaped seal evens out any irregularities between workpiece and chuck surface

Handling

- Any shape or size of chuck made to measure

- Recommended grid size depends on workpiece contour and dimensions

- Clamping area defined by polymer o-shaped seal

- Fine vacuum grid plates for extremely small workpieces in any form

- Acts as a base for many special solutions in connection with special vacuum adapter mats

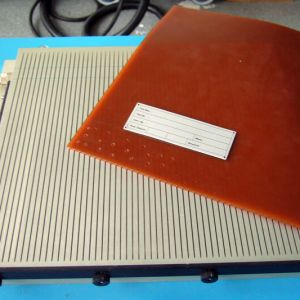

Slot vacuum chucks

Application

- Light milling work

- Drilling (e.g. semiconductors, electronic parts)

- Engraving

Also for complicated workpieces.

Advantages

- Very flat

- Large range of uses (rubber adapter mat can be reused of exchanged)

- Can be used in high speed cutting for precision work with the aid of plane parallel black mats, which can be machined down to achieve optimum accuracy

Handling

- Makes workpiece positioning easier with aid of height adjustable end stops

- Vacuum area can be reduced by using moveable hose connection, masking foil or rubber adapter mat

Perforated-grid chucks

Applications

Highly accurate

- Foils and conductors

Clamping of films and foils on machines used to make printing plates during laser and UV exposure of films

Advantages

- Sizes from 1400 x 2000 mm with accuracy of 50 µm

- Vacuum clamping area need not be covered 100%

Handling

- Easy positioning of workpiece with eccentric end stops

- Limited hold down force for machining purpose

FLIP-POD Vacuum System

Application

For mechanical milling or grinding

- Drilling

- Making threaded bores

Mainly for large workpieces made out of

- Wood

- Plastic, glass or cast metals. Suitable for sawn or raw surfaces

Advantages

- Strong hold down forces enable the use of large machines.

- Bevels, contours and radii can be performed on the upper and lower workpiece surfaces

- Clamping dimensions can be changed within seconds to conform to new workpiece sizes

- Can be used on most machine-tables

Handling

- Pods are the contact surface for the workpiece

- Simply activate or deactivate the pods by turning them around

- To clamp a workpiece effectively 6-8 pods are advised

- This modular system can be extended for larger clamping surface

Circular Chucks

Applications

- Optimal clamping of round parts

- Used on lathes

- Circular chucks with Metapor inserts are available for turning small workpieces

Advantages

- Allow fixing of parts with various inner and outer diameters

- Accurate positioning of parts using finite adjustable stops

- Special solutions possible for diameters outside standard from 100 to 630mm

Handling

- Span as aluminium or steel

Vacuum pumps and units

We have all different kinds of vacuum pumps available to meet each individual need. Size and capacities range from 3m³/h – over 500 m³/h to guarantee optimal vacuum clamping fixtures whatever the circumstances.

Liquid ring pumps

Witte offers a liquid ring pump which combines vacuum supply and liquid separator in one. This pump filters gathering coolant during machining process and integrates it into its own water cycle excess fluid is returned to cycle of machining center.

Vacuum units

Operating vacuum required can be generated in many ways. Witte vacuum units feature the following:

- Oil lubricated vacuum pumps with an end vacuum rate of 0,1 mbar absolute at full suction

- Integrated pressure difference switch, which automatically switches the vacuum pump on or off thereby ensuring vacuum during machining, avoiding unnecessary idle running

- Protection switch which safeguards electric motor from overheating

- Air filter which protects pump from dirt (made of acrylic glass with an exchangeable air filter cartridge)

- Careful assembly of compatible components guarantee trouble-free and almost maintenance-free operation using Witte vacuum units in many applications

- Drainage screw for coolants which have been sucked in

- 3m connecting cable with CEE or Schuko plug