ST-Series

Measuring Projector Series

High-end projectors for vertical and horizontal measurement – available in benchtop and floor-standing design. Designed for reliable measurement on the shop floor and in the measurement room.

Areas of use of measurement projectors

State-of-the-art measurement projectors developed by Dr. Heinrich Schneider Messtechnik have earned an outstanding reputation in the world of metrology, setting new standards in terms of accuracy and precision. Designed with consistently high quality, Schneider devices have shown their excellence innumerable times over the past decades.

Since speed and precision are key on the shop floor and in the measuring room, the well-conceived rigid design of the projectors’ physical structure makes a winning team with their robust functional architecture, which is supported by the M2 measurement software (installed as a standard on a tablet PC) and by a high-precision edge sensor. All projectors have been designed to provide easy and intuitive operation to a broad range of users. Since the devices allow measurement operations to be performed in close proximity to the manufacturing area, efficiency is maximised whilst non-productive times are greatly reduced. What better way could there be to save time and money?

ST 360 H – Horizontal measuring projector

The perfect choice for reliable measurement of tools, turned parts, shafts, pipes/tubes and other objects.

Especially when it comes to measuring turned parts, projector ST 360 H shows its particular strengths: Simply place the object to be inspected on the stage of the device vertically, and measurement can begin.

Easy measurement of heavy workpieces weighing up to 50 kg

360-mm projection screen with engraved crosshairs (graticule)

Edge sensor incorporated into the optical path

LED transmitted light illumination

Optional equipment of ST 360 H

LED incident light illumination, dimmable

Swivelling light arm for transmitted light illumination

M3 measurement software with multi-touch panel PC and image processing & analysis functionality (imaging probing system)

Dual-objective (lens) changer (nosepiece)

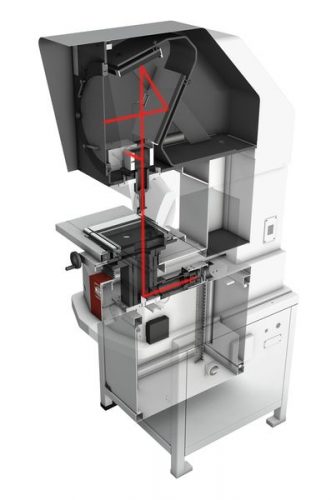

PMP 600 V – Vertical measurement projector in floor-standing design

For reliable measurement of stamped parts, profiles, dies, tools and other objects.

Standard features of PMP 600 V

Large-scale display of the workpiece

Quick adjustment of the measurement stage

Triple revolving nosepiece accommodating different objectives (lenses)

600-mm projection screen with engraved crosshairs (graticule)

LED transmitted light illumination

Optional features of PMP 600 V

M3 measurement software with multi-touch panel PC and image processing & analysis functionality (imaging probing system)

LED incident light illumination, dimmable

Digital angle display for the rotation function of the projection

screen

Laterally displaced column and SK50 manual rotation axis for

measurement of tools with large diameters

Telecentric objectives (lenses) from 5- to 100-fold magnification

Further options are available upon request info(at)dr-schneider.de

Common features of all measurement projectors

Special features and benefits

High acutance (sharpness of contours) for reliable measurement

Smooth and easy operation

Consistent quality of measurement results

No device readjustment required

Measurement of cylindrical and cubic workpieces with consistent accuracy and precision

Reproducible, repeatable and documentable workpiece quality and measurement results

Generation of tabular and graphical measurement reports (protocols)

Standard features

Template holder (support clips)

Protractor, rotatable through 360°, vernier 1’

LED transmitted light illumination

0.001 mm resolution scales

Edge sensor incorporated into the optical path

Device calibration to DIN EN ISO 10360-7

M2 measurement software with tablet PC

Calibrated and adjusted measurement stage surfaces (as a complement and extension to the linear correction function)

Accessories

Black-out device

Rotary stage

Precision vice

Centre point block or manual rotating axis SK40/50

Concentricity gauge

Precision jaw chuck with angle indicator

Workstation 75

Further accessories are available upon request info(at)dr-schneider.de

Internal edge sensor

An edge sensor built into the projector’s optical path ensures reliable measurement results regardless of the ambient lighting conditions at the projector’s place of installation.