Selective Laser Melting Machine SLM 280 2.0

The optimal approach for reliable metal part production and prototypes. Flexible, safe and efficient. Up to 80% higher build-up rate.

The Selective Laser Melting Machine SLM 280 2.0 provides a 280 x 280 x 365 mm³ build envelope and a patented multi-beam technology. During the build process up to two fiber lasers expose the build field via a 3D scan optic. The SLM 280 2.0 is available in several configurations, providing single optics (1x 400W or 1x 700W), dual optics (1x 700W and 1x 1000W) and twin optics (2x 400W or 2x 700W). Depending on how the components are arranged, a 80% higher build rate can be achieved. In addition, the patented bidirectional powder coating helps to reduce the manufacturing time of individually manufactured metal build parts. Thus, the Selective Laser Melting Machine SLM 280 2.0 enables the manufacture of individual metal components based on CAD data for series production and one-off production with individual parameters.

The use of a large powder tank (40l) with two bottles (each 5l) enables the execution of a complete production process in full height with a 1.6-way overdose. The size of the overflows has also been modified accordingly and to enable simple handling, the powder bottles of the overflows are easily accessible from outside.

The complete process is carried out in an inert gas atmosphere. With efficient inert gas circulation, a reduced gas consumption is achieved in a secure and efficient operation. A new inert gas flow is used for optimum process conditions, whereby an efficient removal of flue gas from the process chamber is achieved. In addition to the attainment of constant conditions on the work surface, the beam entry glasses are also effectively protected from contamination.

There is room for cleaning equipment in a compartment in the left side wall of the process chamber so that, after a production process, the build parts can be cleaned of powder while still in an inert gas atmosphere.

Reliable software enables production-ready data formatting for optimized build processes and individual applications. The SLM 280 2.0 as an open system offers many options for optimizing the production processes as required with individually set process parameters and for carrying out material developments. In addition, the defined parameters can be directly transferred to further machines in the series SLM 125 and SLM 500.

An extensive monitoring system that has been developed specifically for the SLM process enables a high level of process control and, as a result, a high level of quality for the build parts.

| Technical Specifications | |

| System configuration for all types of metal powders / Technical changes reserved | |

| Build Envelope (L x W x H) | 280 x 280 x 365 mm³ reduced by substrate plate thickness |

| 3D Optics Configuration, Dual Configuration: with switching unit | Single (1x 400 W), Twin (2x 400 W), Single (1x 700 W), Twin (2x 700 W), Dual (1x 700 W and 1x 1000 W) IPG fiber laser |

| Build Rate | up to 55 cm³/h |

| Variable Layer Thickness | 20 µm – 75 µm |

| Min. Feature Size | 150 µm |

| Beam Focus Diameter | 80 – 115 µm |

| Max. Scan Speed | 10 m/s |

| Average Inert Gas Consumption in Process | 2,5 l/min (argon) |

| Average Inert Gas Consumption Purging | 70 l /min (argon) |

| E-Connection / Power Input | 400 Volt 3NPE, 63 A, 50/60 Hz, 3,5 – 5,5 kW |

| Compressed Air Requirement / Consumption | ISO 8573-1:2010 [1:4:1], 50 l/min @ 6 bar |

| Dimensions (L x W x H) | 2600 mm x 1200 mm x 2700 mm (incl. PSH100) |

| Weight (without / incl. powder) | approx. 1300 kg / approx. 1800 kg |

Visit on SLM Solution here

HIGH TEMP. SUBSTRATE-PLATE HEATING FOR SLM 280

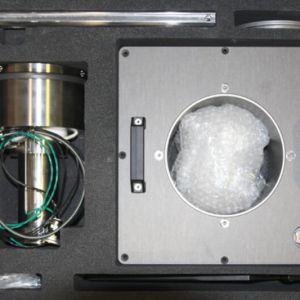

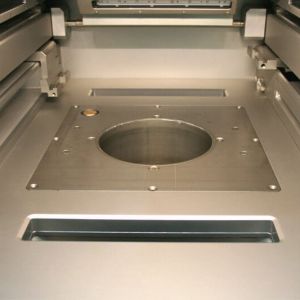

This new retro table heating device does enable temperatures up to 550°C on the substrate-plate. Potential applications are production of Titanium parts without internal stress or cracks. Furthermore future applications in R&D are a target area for the increased heating temperature. The modular design concept of this option does enable a quick mounting similar to the installation of a reduced build-plate in the SLM 280 machine. After this option is installed parts up to a hight of 100 mm and a diameter of 90 mm can be produced. All necessary parts and components will be delivered in a compact tool case. When retro tting this option at older SLM machines the mounting-plate inside the build chamber might have to be replaced as well.

Visit on SLM Solution here