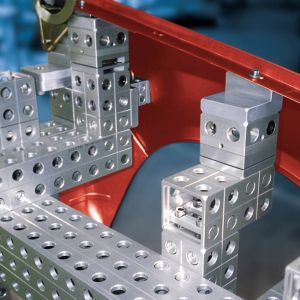

Alufix

ALUFIX – Systematic Reliability

Reliability from market leader in fixture building with 25 years of experience and more than 10.000 systems sold worldwide

Why and when do you need this system?

- You want a fast solution with short reaction times and high flexibility?

- Immediate availability is a must for you because planning time is getting shorter and shorter?

- You want to remain independent and prefer “do it yourself”?

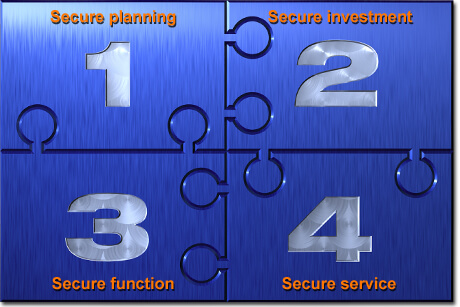

ALUFIX guarantees your success in four ways.

What does this mean?

| Planning reliability |

| ALUFIX shortens your planning time and gives you a high degree of freedom with |

| 100% compatibility |

|

| 100% continuity | |

| 100% availability |

| Investment reliability |

| ALUFIX offers you 4 tangible commercial advantages |

ALUFIX quality standard | |

| 100% quality |

|

| 100% cost effective | |

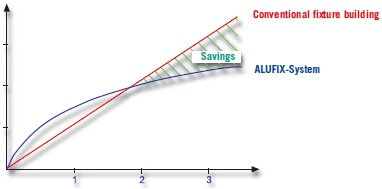

| Compared to dedicated fixtures Alufix gives you a financial advantage already from second application onwards. | Compare cost

|

| 100% recoverability |

|

| Functional reliability |

| ALUFIX saves you time and money, because all tasks are solved quickly and accurately: |

| 100% intelligence | High versatility using patented characteristics |

| 100% easy handling |

|

| 100% speed |

| Service reliability |

| Services around ALUFIX leave nothing to be desired: |

| 100% Service |

|

…innovative technology – a pleasure to work with!

Repeatable workpiece supports for measuring and manufacturing technology

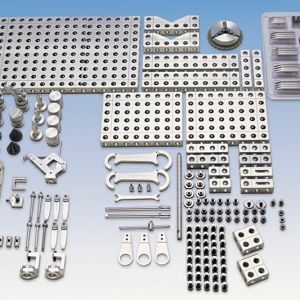

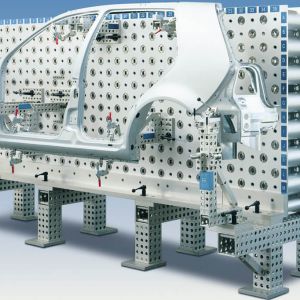

Alufix is a modular fixturing system made out of high-tensile aluminium for measuring fixtures, checking gauges, assembly or welding fixtures, cubings, gauges, meisterbocks, blue bucks, data control models.

It is indispensable in design, R+D and prototyping areas where a lot of changes during development of a product take place

This modular system for holding workpieces is available in six sizes. The different system sizes can be combined with each other. After their useful life fixtures can be disassembled and the single components can be used for new fixtures.

Advantages of Alufix

- high accuracy of all components

- very lightweight but very stable

- system sizes can be combined

- no weight or size limits on workpieces

- all fixtures are repeatable

- components are reuseable

- low storage space required when not in use

- parts library in CAD

- design software

- corrosion free

- longlasting and maintenance free

- component design principle has always been adhered to

System sizes

All sizes in mm

| System | 16 | 25 | 40 | 50 |

| Grid | 16 | 25 | 40 | 50 |

| Gridstart | 8 | 12.5 | 20 | 25 |

| Hole size | 8 | 12.5 | 20 | 25 |

| Bars and Base plates multiple of system size | 16 32 48 64 80 etc. | 25 50 75 100 125 etc. | 40 80 120 160 200 etc. | 50 100 150 200 250 etc. |

Sandwich plates – light, strong, accurate plates

Sandwich plates for measuring and transport

Witte sandwich plates are just as ergonomic and economically intelligent as the fixturing systems. They serve as a basis for measuring fixtures, for mounting complete fixtures, for assembly or transport purposes or as an alternative to conventional granite tables for 3D coordinate measuring machines. They are characterized not only by their light weight, but also high rigidity, evenness and parallelism. All plates can be manufactured with grids and sleeves for Witte PPS and PWS mounting systems or suitable for customer’s own system.

Both the stationary vertical and horizontal sandwich plates can be manufactured according to individual requirements:

- Hovercraft (with independent or mains supply for compressed air)

- Motor driven (x/ y friction drive)

- Cable or radio remote controlled

- Various grids, with or without sleeves

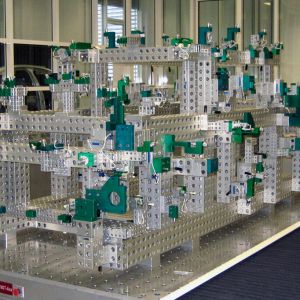

Fixtures & Jigs

Witte modular fixturing systems are used to build all kinds of fixtures i.e. holding fixtures, measuring fixtures or jigs, checking gauges, gap and flush gauges, cubings, meisterbocks, blue bucks, match metal fixtures, tool reference models, data control models etc. etc. The dimensions and accuracy of various types of profile enable rigid configurations in any type and dimension.

We offer complete fixtures and attend our customers from planning through approval process to after sales service. Design is done in CAD by our staff, who are experienced in following our customer’s special requirements. Manufacturing, assembly and measuring is taken care of almost entirely in-house by our experienced staff coordinated by our project managers.

Modular fixturing systems enable fast realization of projects from plan to product. Further time and cost advantages are possible if modifications to finished fixtures are necessary because work pieces change.

Visit on Witte here